Reduce Fuel Consumption Fuel saving is unfortunately the main driver for aftermarket additives. It is understandable, as they are realized NOW. In future as more modern engines (euro 3-5) enter the market, the long-term effect of carbon reduction and lubricity increase will become equally important. There are only a few ways to achieve real fuel savings:

Modern engines are extremely economical but sensitive to fuel specifications, and any deviation will have direct costly consequences. The following substances should be avoided, are harmful and should not be added to fuel in mass volume as they change the composition of fuel negatively or have direct negative effects. Oil companies may use small quantities or some countries extensively modify engines to accommodate the negative aspects directly related to these elements. No detergents, surfactants, aromatics, metals, nitrogen, hydrogen, methanol, ethanol or any alcohol, octane-enhancing, emulsifier bases or cetane number boosting should be utilized. These may have attractive short-term benefits but have severe long-term consequences. Test for optimal package with short and long-term benefits. Caution: Composition of the

iFleet Product How it works - altering

fuel characteristic structure Detailed explanation in: Open wax structure of fuel Fuel is the single largest component cost, but maintenance cost, especially engine failure related cost, is rocketing and increased wear is directly affecting the economy curve. That is why everything is not just about fuel but also engine longevity. The fuel savings that we can realistically achieve in normal condition with modern engines are between 5-7%. See iFleet fuel catalyst section for our achievements and why our catalyst is in its own league, both in composition and multiple benefits.

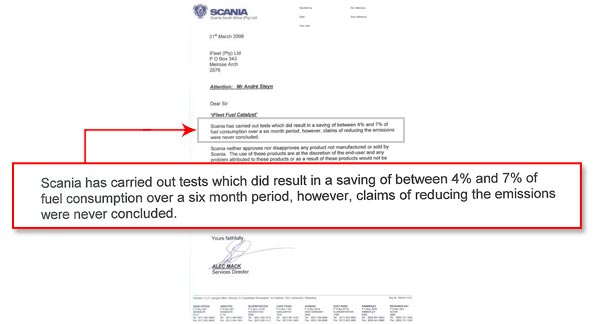

Oem warranties

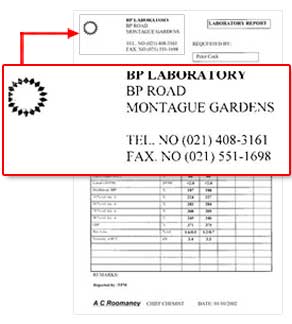

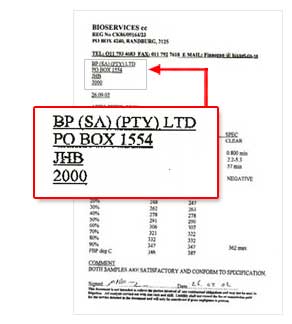

Main board director of OEM confirm Fuel Savings in Writing. Note that the benefits of lowering carbon in combustion chamber and the material lubricity increase is of equal importance, if not exceeding fuel saving in long run. Compliant to fuel specification Oil company laboratory report on spec and third party testing commissioned by Oil Company

Fuel is the largest single component cost, but maintenance cost especially engine failure related cost are rocketing and increased wear is directly effecting the economy curve that is why everything is not just about fuel but also engine longevity. Clean engines with less wear are more fuel-efficient over the entire lifecycle. Saving fuel: Fitting of anti siphoning devices Articles

of interest |

Copyright iFLEET© 2007

Site design by G-spot

iFleet fuel catalyst is capable of opening up the structure of the

fuel by the incorporation of a long unbranched hydrocarbon. This

hydrocarbon is capable of interfacing with the normal carbon chain

of the fuel, thereby opening the structure to enable more oxidation.

This allows easier ignition of the fuel , thereby allowing it to

combust far easier with enhanced, more efficient burn being achieved.

A direct consequence of the improved burn is the reduction of carbon

in the combustion chamber. A material lubricity increase enhances

fuel pump and injector life.

iFleet fuel catalyst is capable of opening up the structure of the

fuel by the incorporation of a long unbranched hydrocarbon. This

hydrocarbon is capable of interfacing with the normal carbon chain

of the fuel, thereby opening the structure to enable more oxidation.

This allows easier ignition of the fuel , thereby allowing it to

combust far easier with enhanced, more efficient burn being achieved.

A direct consequence of the improved burn is the reduction of carbon

in the combustion chamber. A material lubricity increase enhances

fuel pump and injector life.