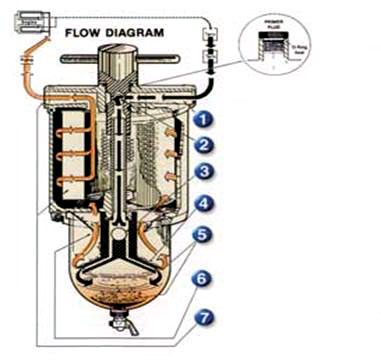

iFleet Automated pressure & coalesce water separator /filtration Benefits:

Ideal for most small bousers with flow rates lower than 150 litres per minute Allows effective upstream removal of water contamination before entering a vehicle’s fuel tank. No monthly replacement of cartridges resulting in materially lower monthly operational costs Highly effective at any sample interval, during and throughout operation Fully automated water drop into separate flameproof container. Handles bouser flow rates up to 150 litres per minute. If the 150 litres per minute is exceeded then the filters are fitted in a parallel configuration. Not a water -wax based absorption media whose efficiency deteriorates as it reaches saturation or is diversely affected by dirt contamination and then has a direct drop in efficiency Applications

Why effective upstream water separation/ filtration? Diesel is hydroscopic and when it leaves the refinery water is already present.It is a magnet for water throughout its existence. Inadequate storage facilities and neglected housekeeping increases your total costs exponentially as you migrate to new technology. ADE engines could run with as high as 8 % water suspended in the fuel for short distances, thus virtually turning into “a steam train”, as they only had injector pressures of 170 bar with huge clearances. That is why most “snake oil” fuel additives have large quantities of emulsifiers or surfactants and thus should be avoided. In all common rail engines all contamination – both particle and water -is fatal to their performance or failure. Minute free water droplets are problematic. Therefore it could be costly to only rely on the onboard water filters to cope with all volumes of water contamination, as water levels directly impact on efficiency, and they all have capacity constraints. What does free water do? Avoid additives that are emulsifiers or surfactant based - it can be costly

How it works

|

Copyright iFLEET© 2007

Site design by G-spot