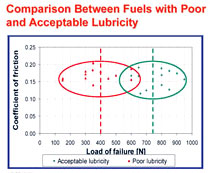

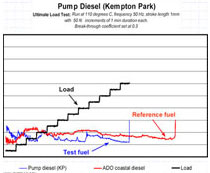

| Increase Fuel Lubricity Lubricity increased 42 -48% on dosing ratio 1:500 as tested on HFFR iFleet fuel catalyst materially improves the lubricity of the fuel, protecting injectors and pumps from premature wear and failure. The product helps to combat problems associated with "diesel spiking" and water, always a concern with outside filling. This leads to prolonged and improved injector spray patterns, which results in extended efficiency of the fuel-burning process, less heat, less soot and improved all round efficiency.

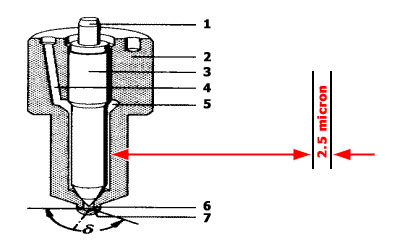

Pressure in these injectors is commonly between 1600 -2500 bar,

with very small tolerances.

Parrafin (A1) To protect one against this third party "spiking" that is highly illegal and not recommended, we offer the fitment of an onboard automatic dosing system which doses iFleet fuel catalyst, in a ratio of 1:500. This will ensure that "spiked diesel" with up to 20% dilution will remain well above the 460N required lubricity level.

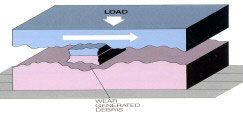

Water finding paste is a good indicator of free water on the bottom of a bowser. Fuel sampling from failed engines clearly demonstrates that lubricity is one of the leading direct contributors of engine sezuires The modern engine is extremely sensitive to low lubricity and injector failure can occur in a short time frame, leading to costly engine failures. Material worn from

the spray holes cannot be replaced

Wear in the sliding area between Plunger and Barrel will result in a reduction in the injection pressure through the spray holes and poorer atomization. Squirting and dribbling are believed to be the cause of the very premature failures associated with liner glazing and excessive carbon build up around the rings. Worn material cannot be replaced, but improved lubricity and viscosity between the Barrel and the Plunger can eliminate slow response and stiction. Premium Diesel Fuel

Diesel engines will run on a great variety of fuels, but some fuels will give better performance, higher efficiency, improved reliability, or lower maintenance costs than others. Fuel must be selected based on overall operating costs, not just on price. Operators must select fuels to optimize performance and emissions.

|

||||||||||||||||||||||

Copyright iFLEET© 2007

Site design by G-spot