| Reduce Contamination

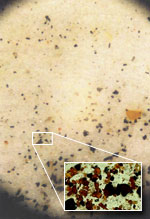

Contamination occurs in various forms and mediums. The smaller the particle size, the greater the degree of contamination. The amount of sub 5 micron contamination increases exponentially in any volume of diesel in relation to 5 micron and larger particles.

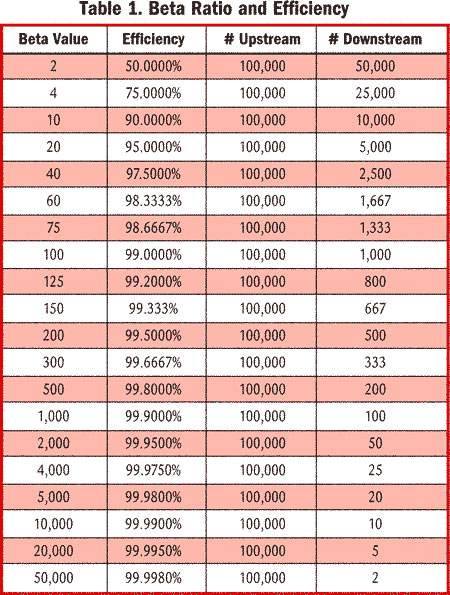

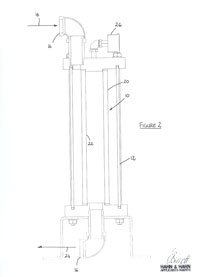

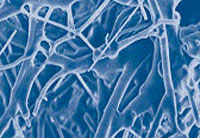

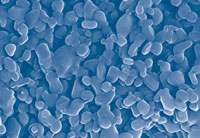

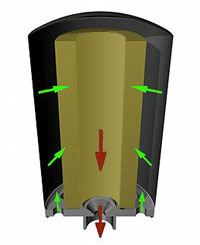

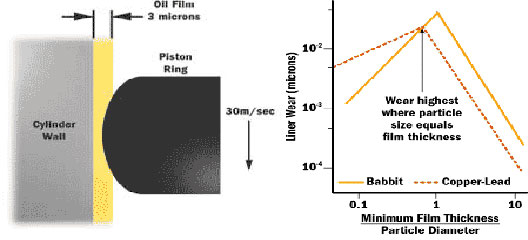

iFleet Depth filtration - ceramic media Setting a new benchmark for cost effective, sustainable cleanliness levels. Applications in any Medium: air, gas & liquid with any flow rates, pressures (high or low), surges and heat with total structural integrity. Providing cost effective sustainable cleanliness levels. iFleet Depth filtration IFleet Depth filter media is the result of years of research and development. The main criteria was to develop a micron depth filter media, which was not sensitive to water and had structural integrity to enable Beta stability.The result is a media that outperforms current market standards and is totally unique. Therefore we patented it. Lowering contamination levels upstream at bouser and downstream on the fiscal vehicle improves physical wear patterns and extends lifecycles vastly. Especially as most vehicle’s filter’s final filtration ability is only in excess of 5-micron particle size, based on an absolute rating utilising surface filtration with limited dirt holding capacity Why is filtering so critical? Why is fuel systems the number one contributor to engine failures? Contamination in diesel has a direct negative impact on lubricity and increases wear patterns exponentially or directly cause component failure. Some of the clearances in engines can be as tight as 2 Micron in injectors at pressures of 1800 – 3500 bar; and in the combustion chambers there is a ring gap of 0.09-0.12 mm or 90-120 micron at pressures up to 230-280 bars. Contamination in the fuel can adversely affect the performance and reliability of the combustion components and this will affect the overall efficiencies (carbon generation, heat, oil, emissions and fuel), lifecycles and failures. The more contamination is excluded from entering the fuel and filtered upstream the more reliable and effective the down stream filters can “cope” with contamination

Coagulation and separation Bouser iFleet Depth micron filtration

On-Line Cleanliness Monitoring Devices provided –mini mesh sampling points: at any time the sustainable cleanliness levels can be monitored by simply sampling before and after ceramic filter. We cost effectively address the entire contamination blueprint on various levels and set new standards! Ceramic spin-on depth filtration filters Depth filtration has changed the way you can clean your fuel for maximum performance, better emissions and less breakdowns, by simply using ceramic filter media. We have been able to restore the fuel cleanliness standards by which engine manufacturers have designed the new age diesel motor. Depth filters not only filter out much finer particles of contamination, but also a great deal more and keeps them locked in, ensuring that no abrasive particles can pass through to your injectors and injector pump thereby causing severe damage, which in turn increases fuel costs, break- downs, down time and pollution. Ceramic filter media are highly cost effective due to the longer service intervals.

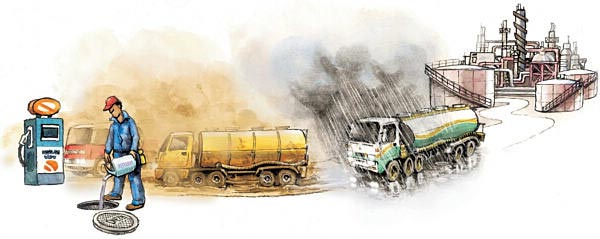

Ideal for small home bases, farmer’s tanks 2200ltr, mobile tanks/bouser, vehicles, machineries, construction equipment and especially for rental equipment. Ceramic setting a new benchmark in sustainable cleanliness levels through cost effective depth filtration without the associated complications of cellulose depth media  Fuel supplier delivering Diesel Fuel supplier delivering Diesel

Particle contamination during a normal fuel tanker delivery (top view)–with in SABS specification of 25 mg per kilogram: That is 25 g per 1000 litre or 25 kg per 1 000 000 litre.

The particle contamination combined with water contamination through the breathers, together with a dirty fuel bouser is a winning formula for exacerbated fuel deterioration. This process is totally preventable. See iFleet fuel kidney recirculating filtration systems for fuel bowsers and genset (link) Adding fuel to the fire is the way bousers are filtered with virtually no sustainable cleanliness levels. The importance of sustainable upstream filtration can not be over dramatized. To lower total contamination levels throughout the whole fuel blueprint, is fundamentally critical to lowering high contamination levels before it reaches /hits OEM filters. This is of vital importance as excessive contamination levels directly impact on the filter’s efficiency and dirtholding capacity and can lead to diminished effectiveness or total failure of the filter media .ASK your own OEM national service managers. Are you only “filtering” or do you have sustainable cleanliness levels?

Important: Note if a wax- based water absorption media is used, its efficiency is adversely affected by particle contamination .A direct drop in efficiency of water removal is problematic, especially in modern engines. The situation is exacerbated if there are no air breathers installed on the bouser or water levels are not being monitored or if a kidney system has not been installed. Ceramic filter media can’t break. It retains dirt (silica and metal particles) , therefore sustainable cleanliness levels are now cost effectively obtainable for large fuel volumes. Ceramic filter media are available in spin-on or custom filter banks. Oil companies. The current market trend is for the fuel user to own their own fuel site and if he is serious about contamination to effectively address it directly to his own cleanliness requirements. Areas where ceramic filtration are setting new bench marks in sustainable cleanliness levels by setting new industry standards

Coagulation and separation Being a depth media of micron level it separates the clogging of hydrocarbons and thereby reverses the natural deterioration process (agglomerations) by physically splitting all clots. As diesel deteriorates, this will result in improved oxidization of fuel and therefore improve the combustion process Separating clogging of hydrocarbons and thereby reversing the natural deterioration process The effects of and process by which diesel fuel "ages" in storage are well documented in the literature. The agglomeration of fuel particles is promoted by the presence of contaminants in the fuel. This clustering of fuel inhibits combustion, leading to inefficient burning and premature filter clogging.  DEEP DEEPThese are direct quotes from www.deep.org This is the result of years and millions of dollars of studies by the mining industry, OEM’s, health departments and unions. Read their website it is highly informative www.deep.org reports on emissions in mines read full report in literature Injection Pump or Injector Failure: “The fuel injection system is the most complex of all engine systems to maintain. The components are precision engineered with extremely close tolerances. For this reason the basics of maintenance and especially cleanliness are the most important considerations here”

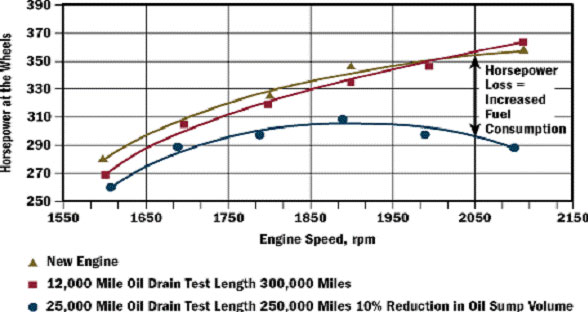

“This problem is usually associated with fuel contamination and is the most expensive to correct. This type of failure will normally result in noticeable performance loss. The engine will be hard to start, will lack power, and have poor acceleration. The engine will suffer from excessive fuel consumption and increased emissions; the most noticeable effect will be a rapid increase in black smoke and CO emissions. Operation under such faulty conditions could lead to engine overheating, and eventually total engine failure.”

“Examine the filters that are being used and the criteria used for selecting them. Price is absolutely NOT the criteria by which filters should be selected for underground diesel engines. Performance and protection are all that matters here. Filters should be whenever possible and should not pass particles larger than 5 microns. “Use a filtered vent on the fuel tank. An open vent draws dirt continuously while the engine is drawing fuel. This “Even if the best quality fuel is used, it will become contaminated if not handled and stored properly. “The fuel systems of most diesel engines are equipped with water separators and two-stage fuel filters. Machine - Extracts from www.deep.org literature. Atmospheric iFleet DEPTH micron breather -air ventilation on bouser (particle and water)

Diesel fuel is like a magnet for both dirt and water. By removing the water, you also eliminate the life source for anerobic bacteria, as well as those organisms that need water to live. Unfortunately the by-product of bacteria and algae inside the tank, is that they eat the inside surface of the fuel tank, leading to tank failure and environmental problems.

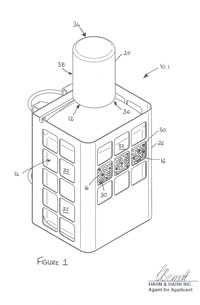

The breather generally lasts 6 months or longer depending on climatic

conditions and the level of airborne contamination. The unit will

clearly indicate that it needs to be changed by changing colour

from white to pink; alternatively it should at least be changed

once a year. The breather is designed for use on all diesel fuel storage tanks and has a flow rating of 500 Liters per minute. The tank breather is effective and inexpensive. It is much easier and less costly to change air breathers and keep the fuel clean to start with than to change fuel filters or clean fuel bousers, especially when a truck is hundreds of miles from home!! Three models

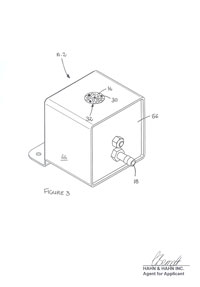

Atmospheric iFleet DEPTH micron breather -air ventilation on vehicle (particle and water)

Fuel tank breather pipes open to atmosphere

“suck“ up dirt and water vapor

equal to suction power of fuel flow to engine. The patented designs and media help to efficiently prevent airborne dirt and water contamination from entering tanks. They are designed to prevent water and contaminants from entering fluid reservoirs as differential pressures occur through thermal expansion, contraction of the fluid and mostly during driving. They directly reduce particle and water-contamination, help provide longer filter life, and reduce equipment wear. Currently in the market most of these breathers are without any filtration, both particle and water. As the truck drives the fuel is sucked from the tank that creates a suction power of air through the breather pipe and all the dirt dust partials are then sucked into the tank through the breather pipe. This problem is exacerbated as these breather pipes are virtually always behind the wheels, which creates a dust cloud in conjunction with the truck’s motion. Water vapour is also sucked into the tank and during the night these vapours condense into water inside the tank. It is recommended that the filters be replaced on a yearly basis or in mining or coastal regions that they be replaced every six months. The complete unit is simply removed and discarded. Breather Filters are powerful preventive maintenance tools designed to protect virtually all types of industrial and commercial equipment that contain hydrocarbon and other non-aqueous fluids. The micron breather is incredibly effective for standby generator tanks where fuel resides for long periods and deteriorates rapidly; creating fuel filter blockages that will shut down a standby generator in a short time of operation. The micron tank breather is inexpensive insurance for your diesel engine, standby diesel generator, or any product you want to keep clean and dry. It is much easier and less costly to change air breathers and keep the fuel clean to start with than to change fuel filters. iFleet DEPTH micron filtration on truck fuel line

We are in the process of testing with OEM’s and large fleet

owners. The product release is scheduled for the 2nd quarter 2008. Benefits of Filtration Adding the above innovative filter range to your current operation is a marginal cost that is easily compensated for by the direct higher downstream cleanliness levels and impact on costs, especially component failure and wear. The earlier contamination is combated the lower the downstream volumes will be and the less the filters will have to cope with. Breather filtration is an excellent way to prevent particle and water contamination from entering into the fuel, so that it doesn’t have to be filtered down stream or cause damage downstream. Lubricity is directly negatively affected by particle and water contamination and lubricity with less contaminants increases lifecycles, improves efficiencies and prevents premature failure.. Carbon is lowered due to improved combustion, thanks to less wear and extended efficiency lifecycle. These custom designed initial filters ensure a reduction in down time and maintenance costs, while improving on secondary filter life, reliability and equipment availability. Water filter range to be released mid 2008, these filters will be very economical as they won’t require cartilage replacements and they automatically “dump” free water. It will also assist in filtering “brick” particles. Particle contamination is“ liquid sandpaper” and dirt larger than 0.7 micron and smaller than 5 micron is ”crusher stones” in a modern engine. Lower contamination levels upstream at bouser and downstream on the fiscal vehicle, improve physical wear patterns and directly extend lifecycles.

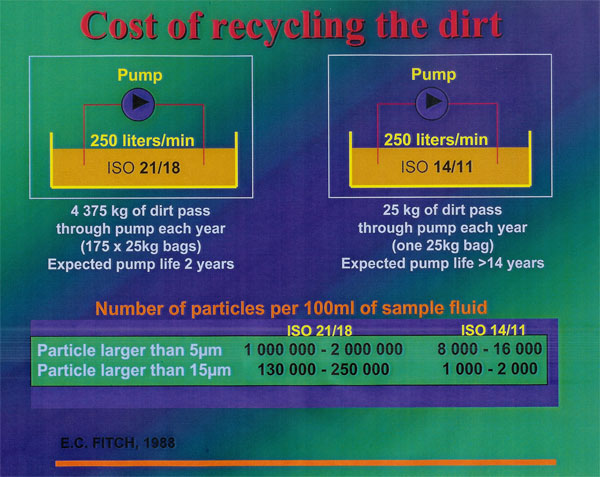

Test done by E.C. Fitch on oil contamination levels. This illustrates

the direct correlation between cleanliness levels and efficiency

lifecycles. By changing ISO level standards, we increased pump life

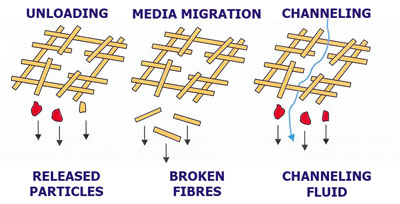

from 2 > 14 years. Why is filtering so critical? Why is fuel systems the number one contributor to engine failures? Contamination in diesel is nothing more than “liquid sandpaper “. It has a direct negative impact on lubricity and increases wear patterns exponentially or directly cause component failure. Some of the clearances in engines can be as tight as 2 Micron in injectors at pressures of 1800 – 3500 bar; in the combustion chambers there is a ring gap clearance of 0.09-0.12 mm or 90-120 micron at pressures up to 230-280 bars. Contamination in the fuel can adversely affect the performance and reliability of the combustion components and this will affect the overall efficiencies (carbon generation, heat, oil, emissions and fuel), lifecycles and failures. The Role of the Filter Reliable Performance: Absolute removal of solids from fluid streams to any micron size specified. High Integrity: Fixed Pore Construction prevents seized particles from being released back into the liquid stream during flow or pressure surges. Resistance to flow or differential pressures: shows how pressure drops across the filter or how much resistance to flow the filter imparts to the system. This resistance has a direct bearing on filter life Collapse Strength: is the minimum acceptable differential pressure at which structural failure of the filter element. This is serious because unfiltered fluid can be routed back into the system. Structural integrity: This ensure that the filter media does not leak due to holes or channeling (where the media simply form channels or collapse) This is serious because unfiltered fluid can simple flow thru the media. Capacity /Efficiency: How much contaminant the filter will retain and the efficiency of the filter is removing the contaminant. Longer Life and Lower Costs: High surface area results in high dirt holding capacity and long element life for lower net operating costs Chemical Capability: This iFleet depth media is compatible with Hydrocarbons and is a media that water has no negative effect of any nature what so ever on. It can even filter 100% water. Most depth filter media are highly sensitive and block with water retention even more so than with particles and shed particles or fibers. Conclusion IFleet Depth filters Depth filtration is closer to the perfect filter as it conforms closer to filter performance criteria. The effective repeatedly micron beta rating is substantially higher than surface filtration and the ultra important beta stability (see ref) uncompromised with our filter media. Therefore capable of continually removing micron contaminant at higher efficiency with vast increase in contaminant holding capacity

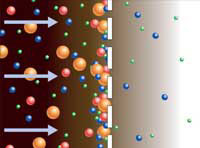

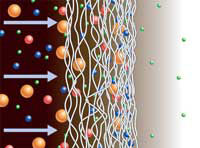

Surface Filtration Surface filtration depends on the availability of a large surface

area of porous screening media to trap contaminants. Among the different

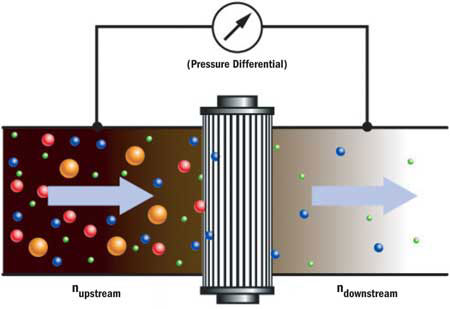

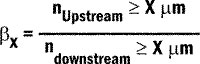

surface filtration media are: Depth Filtration A Combination Filter Selection Nominal Rating Absolute Rating Beta Rating Calculation of Beta Ratios A single multi-pass test is divided into many smaller time segments. During each of these counting periods, the number of particles of a specific size - size x - and greater upstream of the filter is totaled and the number of size x and greater particles downstream of the filter is totaled. The number of particles found upstream of the filter divided by the number of particles found downstream of the filter equals the beta value of the element at the given particle size during that counting period

Efficiency

Table 1 shows the Beta Ratio, corresponding efficiency and the number of particles that will pass to the downstream side of the element for each 100,000 particles seen at the upstream side of the element.

The good design intentions of the application design engineers are often overridden by the sometimes more powerful dictates of price and competition. System suppliers and purchasers often change the filter strategy by changing the filter size, micron rating and the number of filters. This is an easy way to lower the overall system price. The equipment user may then have to add filtration to achieve the required system performance after the system is purchased, installed and operating. Beta Stability A comprehensive filtration strategy designed to maintain the proper target cleanliness for the system can substantially reduce contamination-related failures. Selecting filter elements is a serious undertaking because achieving and maintaining clean fluid begins with filter selection. Filter elements must be compared based on the multi-pass test results. The Beta Ratio, or particle removal efficiency, is also a top selection criteria. Using elements with low Beta Ratios or poor efficiencies, even though the purchase price may be lower than elements with high Beta Ratios or good efficiencies, will inevitably result in much more costly system failures. ISO 16889 Multi-Pass Test

Where x is the determining size of particle for the Beta ratio. The need to remove particles consistently across a wide size range was recognized by the ISO Working Group responsible for updating the multi-pass filter test. The group also stipulated that detailing comprehensive performance data was necessary so users can make informed selections. The data that can be made available is as follows:

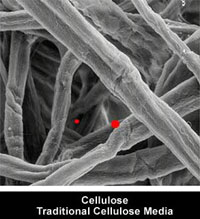

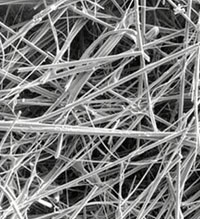

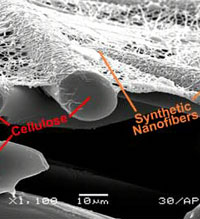

Advantage of iFleet Depth media over “Paper” depth filtration media

Overall the iFleet media is more compliant to the Filter performance Criteria than the“Paper” media is.

The nett effect is that the fuel system and especially the fuel injectors are impacted on negatively across a broad spectrum. These include ncreased injector wear or injector failure, increased combustion heat, soot formation due to poor burning, oil life, increased emissions and fuel consumption. Depth filtration is a proven solution for collection of sub micron contamination Water sensitive: As diesel is hydroscopic with free water and water in suspension, even at refinery level, these filters have a limited life span before they water block. Usually fitted after the fuel pump otherwise cavitations are caused in the fuel line and the fuel pressure is required to form bypass channels to maintain fuel flow. Medium collapse: Most current sub 5 micron filters also have the possibility of filter medium collapse that causes the collected dirt to storm rush the injectors all at once, with a detrimental "sand blast" impact. Short Filter life: Due to particle quantity, the filter holding capacity is limited

Note: Direct correlation between engine advancement and sensitive to water and particle contamination.

South Africa has higher dirt levels consisting of smaller particles This turns particle contamination into “ liquid sandpaper” and dirt larger than 0.7 micron Utilizing ceramic filtration media in fuels is setting a new benchmark Patent Title [Filter]: Ceramic media -a liquid hydrocarbon filter

Reference: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copyright iFLEET© 2006-2010

All content on this site is explicitly copyrighted and absouloutely no duplication

of any material without prior concent will be tollerated

Site design by G-spot

The

material increase in lubricity and reduction of carbon with the

use of iFleet fuel catalyst is a huge step in the right direction

to extend injector life. Combining this with effective filtration

at the required micron level is a proven winner.

The

material increase in lubricity and reduction of carbon with the

use of iFleet fuel catalyst is a huge step in the right direction

to extend injector life. Combining this with effective filtration

at the required micron level is a proven winner. There

exist misalignments in the market place, as most modern engines

are fitted with final filtration of 10 to 5 micron and the injector

clearances are less than 2 micron.

There

exist misalignments in the market place, as most modern engines

are fitted with final filtration of 10 to 5 micron and the injector

clearances are less than 2 micron.

This is not achieving Sustainable cleanliness levels due to limited dirt holding capacity of the spin-on filter (+/_ 160 g), surges and filter media “break” as the differential pressure across the filter increases due to the large numbers of particles blocking and caking onto the synthetic filter media, being forced through due to unloading, media migration and channelling.

This is not achieving Sustainable cleanliness levels due to limited dirt holding capacity of the spin-on filter (+/_ 160 g), surges and filter media “break” as the differential pressure across the filter increases due to the large numbers of particles blocking and caking onto the synthetic filter media, being forced through due to unloading, media migration and channelling.

The

atmospheric breather is air dirt and water filter/breather for use

on the tank vent of diesel fuel storage tanks both above and below

ground. The particle filter media is the iFleet Depth micron filter

along with a desiccant, which removes moisture from the air going

in and out of your tank. By replacing your current tank vent (which

keeps out only bricks and stones) on your diesel fuel storage tank

with the. iFleet Breather, you virtually eliminate the primary source

of dirt and water contamination in your fuel.

The

atmospheric breather is air dirt and water filter/breather for use

on the tank vent of diesel fuel storage tanks both above and below

ground. The particle filter media is the iFleet Depth micron filter

along with a desiccant, which removes moisture from the air going

in and out of your tank. By replacing your current tank vent (which

keeps out only bricks and stones) on your diesel fuel storage tank

with the. iFleet Breather, you virtually eliminate the primary source

of dirt and water contamination in your fuel.  The

iFleet Breather stops this particle contamination from entering

your fuel system. This allows for the down stream bouser and on

board vehicle filtration to be more effective and efficient by simply

having to contend with less volumes of contamination, thus directly

effecting dirt holding capacity and filter media integrity down

stream.

The

iFleet Breather stops this particle contamination from entering

your fuel system. This allows for the down stream bouser and on

board vehicle filtration to be more effective and efficient by simply

having to contend with less volumes of contamination, thus directly

effecting dirt holding capacity and filter media integrity down

stream.