|

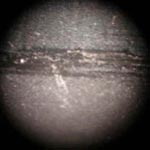

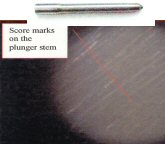

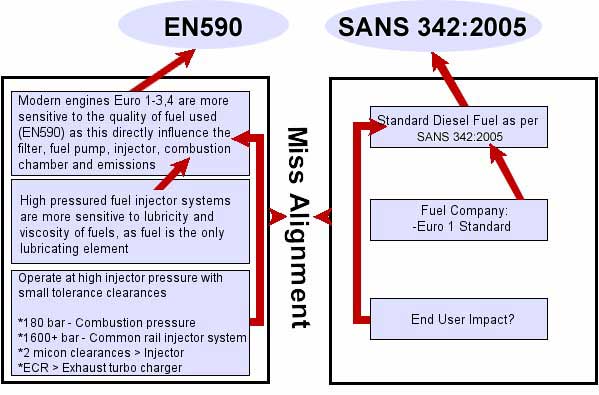

Modern Fuel Injection Systems operate at very high injection pressures with dramatically reduced clearances. One of the main culprits of modern engine failures Low lubricity and contamination (water, particle, surfactants and parrafin) are the two main reasons for injector failure. Please read lubricity and contamination sections for more detail. This simple graph gives an indication on how pressures and tolerances have changed in modern engines with fuel injector pressures exceeding 1800 bar, combustion pressures of 180 bar and micron clearances between moving parts. It is clear that a great challenge is on the horizon as we are now entering Euro 3 standards with Europe at Euro 5 levels. Euro 5 levels can only be achieved by treatment of emissions with either EGR or catalytic converters. The one common challenge is how carbon "soot" generation, lubricity sensitivity and contamination increase exponentially with the change in Euro levels. The more these factors are addressed, the more economically these engines will perform. The slightest deviations on any of these factors will have costly results. iFLEET fuel catalyst is a Material Lubricity Improver, which improves lubricity in all fuels. It even will protect against "Spiked" diesel. Lubricity increased 42 -48% on dosing ratio 1:500 as tested on HFFR

Experience in Southern Africa has shown huge variations in Diesel Fuel. The present picture in Southern Africa shows two trends. The first is obvious in early engine failures, often well within warranty periods. The second is less obvious in reduced power and/or increased fuel usage high exhaust temps shorter engine lives

In summary iFLEET fuel catalyst is a Fuel Additive, which amongst other things, is as a Fuel Saver, Diesel Lubricity Improver and a Fuel Injector Cleaner. The product provides an optimum uniform fuel blend and open wax structures, which promotes complete fuel combustion with reduced toxic emissions and increased lubrication. Engine Builders have been under huge pressure to Reduce Emissions and Improve efficiencies. Fuel Companies have been under pressure to produce Fuels and Oils to satisfy the same demand. Rates of Progress between these two players can vary in different parts of the world |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copyright iFLEET© 2007

Site design by G-spot

Combat

Injector failure

Combat

Injector failure