iFleet Ceramic air breathers for oil and fuel (Micron dirt & water capacity) Ceramic filter medium is not sensitive to hydrocarbon vapors, as fibre surface filter media, is and provides depth filtration of one-centimeter media with a porosity of 33%, which effectively enables long-term air breathers for micron particle contamination. In combination with a desiccant water is also contained, something most breathers don’t accommodate.

This ceramic media enables progression in obtainable cleanliness levels in air breathers, whereas various current market breathers utilize:“pot scourers”, sponges and fibre media only. Remember: South Africa has higher dirt levels consisting of smaller particles Hydraulics “May the force work for you “ Fleetwatch - Dave Scott “And what about the vital but overlooked hydraulic system breather? It has to accommodate the flow rate of air passing into the system as the cylinder is extended. "Breathers should offer a 10 micron or less efficiency," he advises.” Fluid contamination "More than just a broom needed" Fleetwatch - Dave Scott “The forgotten breather - one of the most ignored components of any fuel storage tank or working machinery is the breather. According to hydraulic expert Garnett Cross: "The breather on new equipment is often overlooked for its entire working life resulting in hydraulic pump cavitation because a dirty breather creates pump starvation. A breather is bi-directional - it allows working pressure to escape and draws in from the outside when a machine cools down to attract contaminants unless properly filtered."

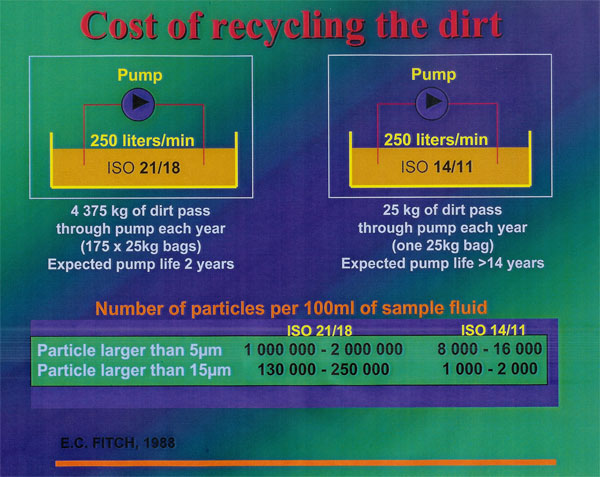

Note the exponential increase of 7-12 million cycles when using effective 3-6 micron particle breathers. iFleet oil breathers prevent oil contamination (Water and Particle) After the success of our iFleet fuel tank breathers and how effective it prevents contamination from entering fuel tank breathers, various entities requested us to adapt and design a full range for oil breathers to effectively prevent contamination (both water and particles) from entering the oil. This made a lot of sense, as contamination in oils is detrimental to wear and oil deterioration.

These Oil breathers only filter “bricks “ and do not prevent water from entering directly or through daily condensation

This clearly demonstrates the destructive abrasive impact of contamination in oil. Surely the idea is to prevent contamination from entering the oil. The impact of effective air breathers can’t be overstated. iFleet Fuel bulk storage tank breathers The atmospheric breather filters the dirt and water from the air and is used on the main air vents of diesel fuel storage tanks both iFleet customizes and sizes for each application from budget applications to huge industrial tanks. Normal cost effective, replace refill only, ideal for diesel drop fills Industrial units fitted with one directional breather valves to allow diesel pressure fills

They are designed to prevent water and particle contaminants from entering fluid reservoirs as differential pressures occur through thermal expansion and contraction of the fluid mostly during driving. They directly reduce particle and water-contamination, help provide longer filter life and reduce equipment wear. These open breathers or inadequate fibre media breathers are a major source of ‘onboard” contamination and negatively affect any upstream fuel bouser filtration.

Air filtration

|

Copyright iFLEET© 2007

Site design by G-spot

above and below ground. The particle filter media is the iFleet Depth micron filter along with a desiccant, which prevents moisture from the air going into your tank. By replacing your current tank vent (which keeps out only bricks and stones) on your diesel fuel storage tank with the. iFleet Breather, you virtually eliminate the primary source of dirt and water contamination in your fuel.

above and below ground. The particle filter media is the iFleet Depth micron filter along with a desiccant, which prevents moisture from the air going into your tank. By replacing your current tank vent (which keeps out only bricks and stones) on your diesel fuel storage tank with the. iFleet Breather, you virtually eliminate the primary source of dirt and water contamination in your fuel.  “According to Olaf Voigt, industrial marketing manager of filtration specialists, Pall South Africa, modern fuel injection equipment runs at very high pressures that demand fuel filtration below 3 microns. "To protect expensive injectors from premature wear, we recommend that 3 micron fuel tank breathers are fitted to diesel fuel tanks with the breather situated high away from the tank," he says.

“According to Olaf Voigt, industrial marketing manager of filtration specialists, Pall South Africa, modern fuel injection equipment runs at very high pressures that demand fuel filtration below 3 microns. "To protect expensive injectors from premature wear, we recommend that 3 micron fuel tank breathers are fitted to diesel fuel tanks with the breather situated high away from the tank," he says. The life- cycle of the filter is based in years and by not utilising the Ceramic filter breather an “Achilles heel” for onboardcontamination is created which is also detrimental to upstream filtration objectives.

The life- cycle of the filter is based in years and by not utilising the Ceramic filter breather an “Achilles heel” for onboardcontamination is created which is also detrimental to upstream filtration objectives.