| Carbon - "Soot" - part of combustion

Due to stop / start driving in cities, extended idling and worsening traffic congestion, the engines are building up vast amounts of carbon everywhere from the injector tips to valves, EGR, turbo's, filters, exhaust system etc. Flameproof equipment suffers from carbon buildup. We reduce the carbon visibly and extend the efficiency due to extending carbon blockage intervals. This effectively improves the combustion process with lower emissions and raises asset utilization due to extending cleaning intervals. The product reduces carbon build-up in engines as a result of improved fuel combustion in the engine chamber, reducing abrasive engine wear and extending engine oil integrity due to less soot and fuel dilution. Materially less carbon during combustion process. Carbon is highly abrasive and affects spray patterns and valvesCarbon is a major growing problem in South Africa and will soon rival lubricity, as we enter the Euro 3 to 5 technology phase. There are a number of reasons, all working collectively to exacerbate soot formation:

Fuel injector system and engine designed specifically for EN 590 (European Fuel spec) compliant fuel?

SA aromatics 42% max of volume in 2006 SANS 342:2005 European EN 590 11 % max of volume in 1999 Note: material difference between number of carbon molecules and nature of carbon bonds between aromatics and paraffins.

Fact on SA Fuels even after the "new diesel". SANS 242:2005 This affects fundamentals of fuel during the fuel injection and combustion process This directly impacts on the efficiency and life cycles of modern engines and the many millions spent on developing engines that are economically and environmentally friendly. This phenomenon affects all modern engines across the world The misalignment of fundamental fuel characteristics is a costly

exercise |

|||||||||

Copyright iFLEET© 2007

Site design by G-spot

The

more modern the engine, the bigger the carbon issue. This is -with

lubricity - the biggest reason to utilize our fuel catalyst. It

is an undisputed fact that we lower carbon during the combustion

process due to improved combustion and increased lubricity that

extends injector efficiency on spray patterns. The fact that we

save small amounts of fuel 5-7% is a purely financial short-term

bonus. The long-term effect is that we extend economical engine

life and lower the possibility of costly engine failures that has

a huge cost impact and negatively impacts on asset utilization.

The

more modern the engine, the bigger the carbon issue. This is -with

lubricity - the biggest reason to utilize our fuel catalyst. It

is an undisputed fact that we lower carbon during the combustion

process due to improved combustion and increased lubricity that

extends injector efficiency on spray patterns. The fact that we

save small amounts of fuel 5-7% is a purely financial short-term

bonus. The long-term effect is that we extend economical engine

life and lower the possibility of costly engine failures that has

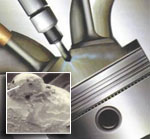

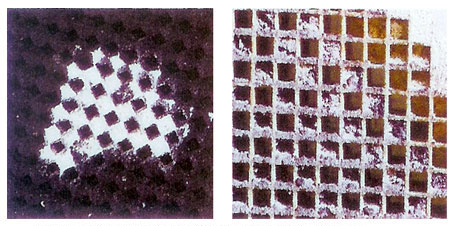

a huge cost impact and negatively impacts on asset utilization. Build

up of carbon on fuel injectors causes poor spray patterns, resulting

in less effective burning of fuel. This affects every element around

the combustion chamber, increasing heat, oil dilution, emissions,

fuel consumption and shortening the engine life cycle. Carbon penetrates

everywhere and is highly abrasive by nature.

Build

up of carbon on fuel injectors causes poor spray patterns, resulting

in less effective burning of fuel. This affects every element around

the combustion chamber, increasing heat, oil dilution, emissions,

fuel consumption and shortening the engine life cycle. Carbon penetrates

everywhere and is highly abrasive by nature.

Material

difference in Aromatic levels (up to 36% of total diesel volume).

Material

difference in Aromatic levels (up to 36% of total diesel volume).